Precision Process Model for Hot-Dip Galvanizing Lines

Against the backdrop of intelligent industrial upgrading, hot-dip galvanizing equipment, as core supporting equipment in the metal surface treatment sector, has become a key factor determining an enterprise’s core competitiveness with its intelligence level and process control precision. Traditional hot-dip galvanizing lines generally suffer from extensive manual control and poor equipment coordination, which severely restrict product quality stability and production capacity. With deep roots in the R&D and manufacturing of hot-dip galvanizing equipment, RITMAN Equipment has developed a Precision Process Model to empower production lines with full-process refined control, helping enterprises achieve transformation, upgrading, quality improvement and efficiency enhancement.

The core value of the Precision Process Model lies in providing an integrated full-process process control solution for hot-dip galvanizing lines. Through its dual-core modules — the Built-in Process Model and the Process Control Model — it fundamentally resolves industry pain points in traditional production: excessive manual intervention, loose control standards, and large product quality fluctuations. As a core carrier for the intelligent upgrading of hot-dip galvanizing equipment, the model deeply integrates RITMAN’s years of process expertise and massive practical project data. It can flexibly adapt to the production needs of various hot-dip galvanizing lines, realize customized and efficient control, fully unlock production line potential, and help equipment achieve optimal performance.

Built-in Process Model: Precisely Optimize Production Flow

Based on over 30 years of galvanizing experience, RITMAN Equipment has developed an MES system with built-in exclusive process models for a full range of products, tailored to different product characteristics, production flows, process impact factors and key operating points. This realizes precise optimization of the production flow and brings greater stability and controllability to product quality.

By collecting key parameters in real time during production — such as zinc bath temperature, conveying speed, galvanizing time and so on — the system dynamically compares and intelligently analyzes these parameters against the built-in process model. It can promptly detect production deviations and automatically generate adjustment plans to ensure every procedure follows the optimal process route.

Furthermore, the system features self-learning capabilities. It continuously optimizes model parameters based on actual production data of different batches, further improving process adaptability and production stability. It effectively reduces quality fluctuations caused by differences in manual experience, providing solid support for the efficient and high-quality operation of hot-dip galvanizing lines.

Process Control Model: Ensure Full-Process Product Quality

According to the production requirements of different products, the system automatically applies the built-in exclusive process control model. The model fully covers core quality-impacting parameters including operating speed, workpiece angle and process duration, achieving precise control over product quality from detailed aspects of the entire production flow and guaranteeing stable quality.

The synergy of the Process Model and Process Control Model drives hot-dip galvanizing lines to improve both quality and efficiency. The application of the Precision Process Model not only fundamentally solves the industry pain point of unstable product quality in traditional lines, but also optimizes the overall operational efficiency of galvanizing equipment and unlocks full production capacity. The Process Control Model realizes intelligent and precise control, effectively reducing production errors and process delays while lowering energy and raw material consumption, making hot-dip galvanizing lines more efficient and energy-saving.

In the future, RITMAN Equipment will continue to focus on the hot-dip galvanizing equipment sector, iteratively optimizing the technical performance of the Precision Process Model. We will provide customized intelligent upgrading solutions for more enterprises, comprehensively empower the quality upgrading of hot-dip galvanizing lines, and support the high-quality development of the galvanizing industry with core technologies.

As an expert in global surface treatment coating equipment and production auxiliary materials, Xuzhou Ritman Intelligent Technology Co., Ltd. always upholds the service philosophy of “Customer-centric, creating value for customers”. We are committed to being a reliable value partner on our customers’ sustainable development path, providing reliable and systematic solutions.

Our core businesses include:

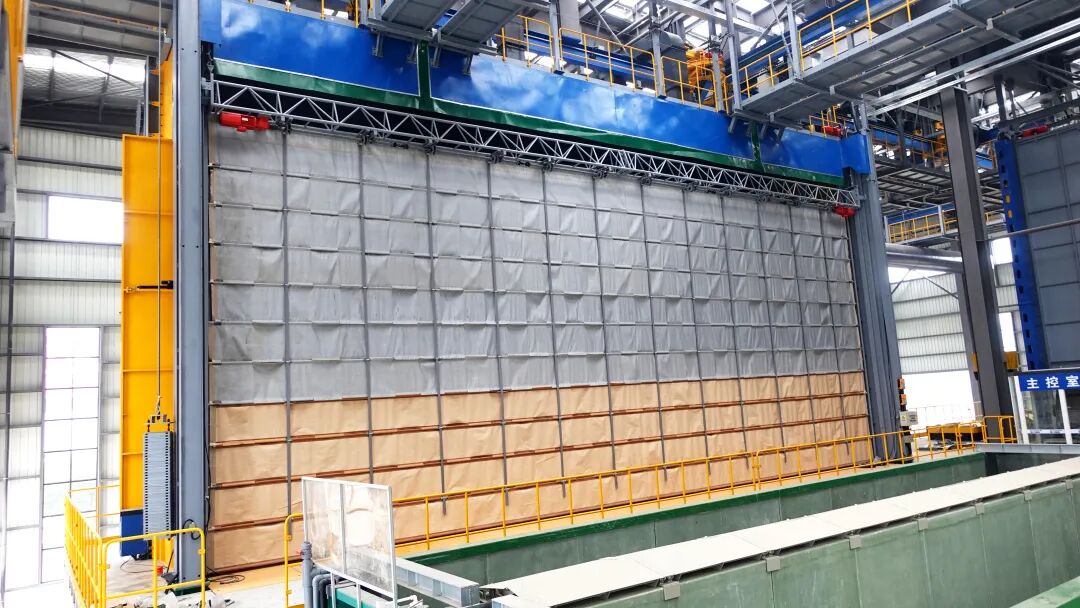

Batch hot-dip galvanizing production lines (hoist galvanizing, centrifugal galvanizing, air-blown galvanizing)

Strip continuous production lines (galvanizing, zinc-aluminum-magnesium, pickling, color coating)

Pickling conversion coating lines (pickling & phosphating, passivation, silane, ceramic conversion, electrophoretic coating, electroless plating, etc.)