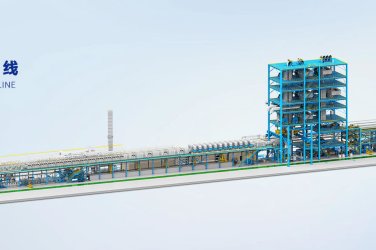

RITMAN Saudi Project: 500 Ton/Day Capacity with Automation & Training

Recently, the Saudi hot-dip galvanizing project undertaken by RITMAN has achieved remarkable milestones in production efficiency. On November 18th, the daily capacity first exceeded 400 tons. In response to the client's request to fully release the furnace galvanizing capacity, the project set a new record just 13 days later—on December 1st, the daily capacity successfully broke through 500 tons. This outstanding achievement fully demonstrates the competitiveness of Chinese intelligent manufacturing in overseas industrial projects through RITMAN's solid technical strength.

The core driver behind this capacity breakthrough lies in the in-depth implementation of RITMAN's mature automated technology system and full-process digital management capabilities. Centered on the core production chain of hot-dip galvanizing, the project has established an intelligent linkage system covering the entire processes of pickling, galvanizing, and post-treatment. By integrating the MES (Manufacturing Execution System), real-time production data collection, analysis, and precise adjustment of process parameters are realized. For instance, in the galvanizing process, the system can automatically match key parameters such as zinc bath temperature and immersion time based on the steel material and thickness, significantly reducing errors caused by manual intervention. Meanwhile, through the digital monitoring platform, managers can real-time track the operating status of all equipment and predict potential failures in advance, which not only avoids production interruptions but also ensures the stability of core quality indicators such as uniform zinc coating thickness and adhesion, laying a solid technical foundation for capacity improvement.

The steady release of production capacity is also inseparable from the simultaneous improvement of the local team's professional skills. To ensure the efficient operation of automated equipment and the accurate implementation of process technology, RITMAN's project team has customized an integrated "theory + practical operation" training program for local employees:

This professional training system not only bridges the "last mile of technology implementation" but also rapidly builds a highly efficient and collaborative local operation team. It enables the full exertion of automated equipment performance and lays a solid talent foundation for the continuous increase of project capacity.

The capacity breakthrough of the Saudi hot-dip galvanizing project marks the successful practice of RITMAN's "automation technology empowerment + localized professional delivery" model in the overseas market. It not only creates higher production value for the client but also provides a replicable benchmark case for the global promotion and application of Chinese intelligent manufacturing technology in the industrial sector.