Continuous Galvanizing Line

Core Technical Advantages

Full-Process Intelligent Control: Equipped with PLC intelligent control system and online detection equipment, it real-time monitors key parameters such as coating thickness, temperature and speed. The fluctuation of zinc coating thickness can be controlled within ±2μm, and the defect detection rate reaches 99.9%, ensuring product consistency.

High-Efficiency Production Output: The maximum operating speed of a single production line can reach 150m/min, with an annual processing capacity of up to 150,000 tons. Compared with traditional intermittent production, the efficiency is increased by 3-5 times, which is suitable for large-scale and mass production needs.

Environmental Protection and Energy-Saving Design: Equipped with zinc fume recovery and purification system, acid mist absorption device and integrated wastewater treatment equipment, the emission of waste gas and wastewater is far lower than the national standard; adopting high-efficiency annealing technology, the energy consumption is reduced by 15-20% compared with traditional production lines, realizing green production.

Wide Adaptability: It can process various cold-rolled/hot-rolled steel strips with thickness of 0.15-3.0mm and width of 900-1800mm, and supports customization of different zinc coating thicknesses (80-275g/m²), meeting the coating requirements of products in construction, home appliances, automotive and other fields.

Stability and Reliability: Core components are made of high-temperature and corrosion-resistant alloy materials, and the service life of the zinc pot is as long as 8-10 years; modular design facilitates installation and maintenance, greatly shortens downtime for maintenance, and improves equipment utilization rate.

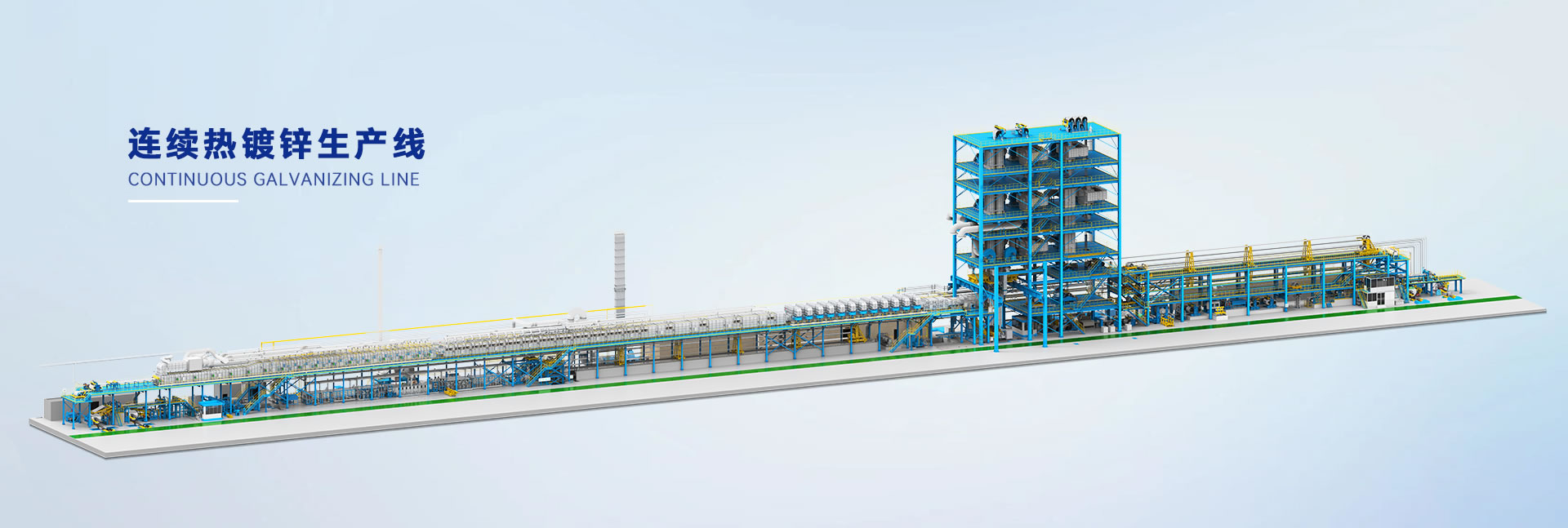

Continuous Galvanizing Line

Our galvanizing line is a high-end galvanizing equipment integrating automation, intelligence and environmental protection, specially designed for the continuous coating processing of coil products such as steel strips. Adopting advanced continuous hot-dip galvanizing technology, the production line realizes the full-process automated operation from substrate uncoiling, cleaning, annealing, galvanizing, zinc coating control to finished product coiling. It can accurately control the coating quality and production efficiency, and is widely used in steel processing, construction materials, home appliance manufacturing and other industries, providing a stable and reliable solution for large-scale galvanized coil production.

Core Technical Advantages

Full-Process Intelligent Control: Equipped with PLC intelligent control system and online detection equipment, it real-time monitors key parameters such as coating thickness, temperature and speed. The fluctuation of zinc coating thickness can be controlled within ±2μm, and the defect detection rate reaches 99.9%, ensuring product consistency.

High-Efficiency Production Output: The maximum operating speed of a single production line can reach 150m/min, with an annual processing capacity of up to 150,000 tons. Compared with traditional intermittent production, the efficiency is increased by 3-5 times, which is suitable for large-scale and mass production needs.

Environmental Protection and Energy-Saving Design: Equipped with zinc fume recovery and purification system, acid mist absorption device and integrated wastewater treatment equipment, the emission of waste gas and wastewater is far lower than the national standard; adopting high-efficiency annealing technology, the energy consumption is reduced by 15-20% compared with traditional production lines, realizing green production.

Wide Adaptability: It can process various cold-rolled/hot-rolled steel strips with thickness of 0.15-3.0mm and width of 900-1800mm, and supports customization of different zinc coating thicknesses (80-275g/m²), meeting the coating requirements of products in construction, home appliances, automotive and other fields.

Stability and Reliability: Core components are made of high-temperature and corrosion-resistant alloy materials, and the service life of the zinc pot is as long as 8-10 years; modular design facilitates installation and maintenance, greatly shortens downtime for maintenance, and improves equipment utilization rate.

Core Composition and Process Flow

Core Composition: Uncoiler, welding machine, degreasing and cleaning section, annealing furnace, zinc pot system, air knife control device, cooling section, passivation section, coiler, intelligent control system, environmental protection treatment equipment.

Process Flow: Substrate Uncoiling → Butt Welding → Degreasing and Oil Removal → Pickling and Rust Removal → Water Washing and Drying → Annealing and Reduction → Hot-Dip Galvanizing → Air Knife Thickness Control → Cooling and Solidification → Passivation Treatment → Finished Product Coiling

Application Scenarios and Service Guarantee

Application Scenarios: Galvanized coil production in large steel enterprises, processing of base materials for building roof panels/wall panels, coating treatment of home appliance casings/accessories, galvanizing of steel strips for auto parts, processing of steel materials for municipal infrastructure, etc.

Service Guarantee: Provide full-process turnkey services from site planning, customized production line design, equipment manufacturing and installation, commissioning and production to later operation and maintenance training; each equipment is accompanied by detailed technical data and quality inspection reports, with a 1-year warranty period, and lifelong supply of spare parts and technical support are promised.