Blowing Galvanizing Line

1. The automatic hot-dip galvanizing line for steel pipe realizes fully automatic pickling in the closed room, while ensuring the efficiency of pickling. It realizes automatic replacement of pickling slings to avoid bringing in flux liquid into the pickling tank, thus to achieve the purpose of using clean acid.

2. Optimised design of galvanising equipment, simpler operation, lower noise, higher stability and easier maintenance.

3. Automation and informationization of the whole system, which facilitates the control of production costs and the improvement of product quality.

4. A more rational production line layout based on the production process.

5. Reasonable production line equipment selection, energy saving and consumption reduction is more prominent.

Blowing Galvanizing Line - Tubes, Highway fences, Angles

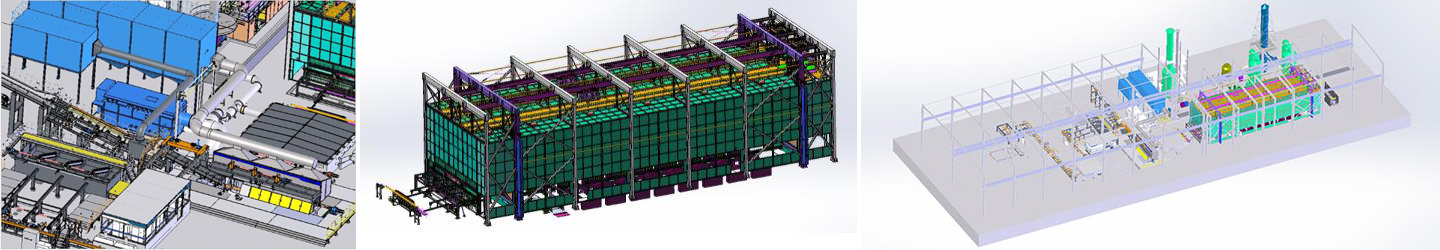

Our fully automated steel pipe hot-dip galvanizing line integrates intelligent robotics, automated logistics and closed-loop control, producing high-quality corrosion-resistant galvanized pipes with minimal human intervention. Full process: Feeding → Pickling → Rinsing → Fluxing → Drying → Hot-Dip Galvanizing → External/Internal Blowing → Air Cooling → Water Quenching → Passivation → Drying → Laser Marking → Stacking → Packaging

I. Fully Enclosed & Automated Pretreatment System

Fully enclosed design with automated RGVs and smart fixtures; operators avoid acid zones, enhancing safety and environmental performance. Unmanned workflow (1 operator for initial loading only):

• RGV #1: Delivers empty fixture to heavy-duty station; transfers steel pipes to low/high-acid tanks for rust removal; returns empty fixture to feeding area.

• RGV #2: Moves pipes from high-acid tank through 2 rinsing tanks to fluxing zone; auto belt-changer transfers pipes to overhead conveyor.

• RGV #3: Transports fluxed pipes to galvanizing entry area.

Benefits: Reduced labor/acid/energy consumption; minimized chemical waste/emissions; low-cost, stable, eco-friendly operation.

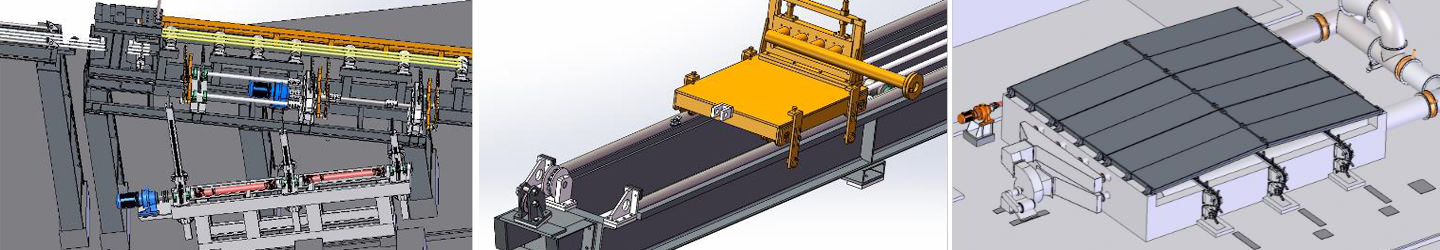

II. Intelligent Galvanizing & Post-Treatment Unit

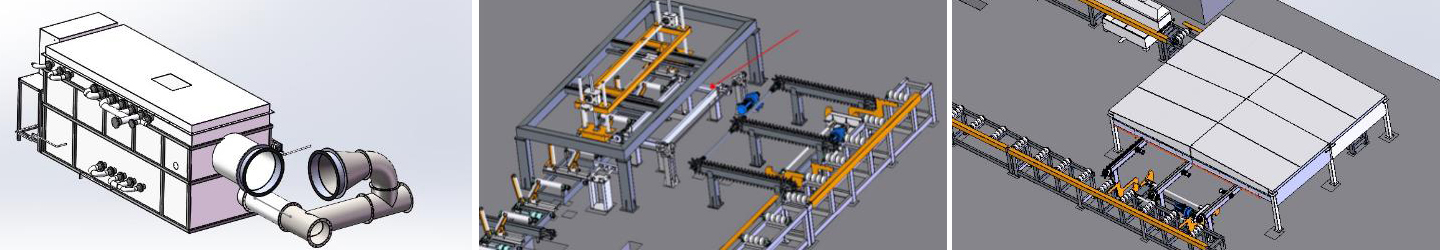

After drying, pipes are auto-conveyed to galvanizing machine. Post zinc bath immersion, key processes activate:

• Blowing System: High-pressure air (external) controls outer coating thickness; compressed air/steam (internal) removes excess zinc (unobstructed passages).

• Subsequent Processes: Air cooling + water quenching (zinc layer solidification) → optional chrome-free passivation (enhanced corrosion resistance) → secondary drying (moisture removal) → laser marking (specs, batch numbers) → robotic stacking/packaging (preset quantities, auto bundling, transfer to discharge buffer).

III. Smart Management & Green Support Systems

1. Auxiliary Systems

• Spent acid regeneration & wastewater treatment

• Acid mist scrubbers & zinc fume collectors

• Waste heat recovery & green energy management

2. Intelligent Manufacturing System

Real-time access for operators/managers to:

• Product quality analytics

• Energy consumption monitoring

• Live production output tracking

• Dynamic process visualization dashboards

With end-to-end automation, standardized operations and strict quality control, this line is a smart manufacturing benchmark in China, setting new standards for sustainable steel pipe corrosion protection.