Future development trend of acid pickling and phosphating technology: intelligent, green and efficient

The metal surface treatment process is undergoing a profound transformation. As a fundamental step, the development of acid washing and phosphating not only affects the competitiveness of individual companies but also impacts the quality foundation and environmental progress of the entire manufacturing industry chain. In response to increasingly stringent environmental regulations, rising energy costs, and higher customer demands for product performance, acid washing and phosphating technology is rapidly evolving towards smarter, greener, and more efficient methods, presenting a new landscape for the industry.

Green transformation is the lifeline of survival and development. In the traditional pickling process, acid consumption, metal impurities, high water consumption and other problems have become the pain points of the industry.

Technological innovation is fundamentally reshaping the path of clean production: phosphorus-free and low-phosphorus conversion film technology is gradually maturing, ensuring the adhesion and corrosion resistance of coatings while reducing phosphorus pollution at the source. The use of new environmentally friendly acid washing aids effectively suppresses acid mist dispersion, improves workshop conditions, and reduces the pressure on subsequent neutralization processes. A breakthrough in wastewater treatment is particularly crucial, enabling high-purity separation of metal ions from water in rinse wastewater. The recovered metals can be reused, and the purified water can be directly recycled for production lines, truly approaching the goal of 'zero discharge.'

The establishment of resource recycling mode not only reduces the environmental compliance risk of enterprises, but also creates additional economic value through resource recovery. Environmental protection input is changing from "cost item" to "benefit item".

Efficiency is the key engine to enhance industrial competitiveness. This is reflected not only in the lean optimization of process links, but also in the deep potential of comprehensive energy consumption.

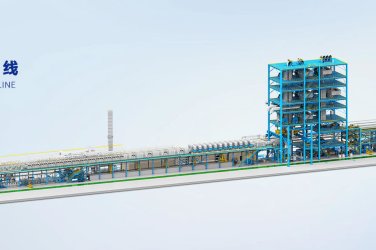

The multi-stage countercurrent washing design significantly reduces the fresh water consumption per unit of product. The tank structure and spray system, optimized through fluid dynamics simulation, ensure more uniform coverage of the chemical solution, reducing processing time by nearly 30%. An efficient acid washing and phosphating line that integrates intelligent temperature control, precise dosing, and online monitoring can reduce overall energy consumption by nearly 40% compared to traditional production lines. Under the 'dual carbon' goals, this energy-saving and efficiency-enhancing capability directly translates into cost advantages and carbon asset value for enterprises.

More importantly, efficiency not only refers to a single production line, but also to the breakthrough of process integration. The compact serial design of pickling, phosphating and other processes reduces the transfer and waiting time of workpieces in intermediate links, and makes the overall production beat nearly double, providing the underlying support for large-scale customized production.

New trends inevitably come with new challenges. Intelligent upgrades require companies to integrate cross-domain technologies, and the scarcity of versatile talents who are proficient in both processes and data has become a bottleneck. The development of green materials is time-consuming and requires significant initial investment, placing small and medium-sized enterprises under dual pressures of funding and technology. Efficient transformation involves restructuring production lines, and the potential short-term losses from shutdowns must be carefully considered.

However, the challenges also present greater opportunities: companies that lead in intelligent transformation will establish a barrier of process databases, creating a know-how advantage that is hard to replicate; suppliers with core green technology will gain an edge in the global environmental supply chain restructuring; and the cost advantages from efficiency improvements will directly enhance their pricing power and profit margins in the highly competitive market.

The advancement of acid washing and phosphating technology goes far beyond the optimization of process parameters. This is an industrial upgrade that integrates digital innovation, green concepts, and efficiency. As production lines begin to think independently, wastewater is transformed into resources, and every joule of heat is maximally utilized, the future of metal surface treatment is becoming increasingly clear —— a smarter, cleaner, and more efficient manufacturing paradigm, laying the foundation for high-quality development.

◆◆◆

About RITMAN Intelligence

Xuzhou RITMAN Intelligent Technology Co., Ltd. is a national high-tech enterprise specializing in metal surface treatment and coating equipment. The company's acid washing and phosphating division offers a range of surface treatment solutions, including acid washing and phosphating, acid washing and saponification, acid washing and passivation, acid washing and auxiliary plating, and chemical plating. These solutions enable the automation, visualization, informatization, and greening of production lines, tailored to the specific characteristics and process requirements of workpieces. They enhance production efficiency and product quality while reducing costs, thereby supporting the company's goal of green and sustainable development.