RITMAN Pre-sales Customized Service

2026/01/09 16:08

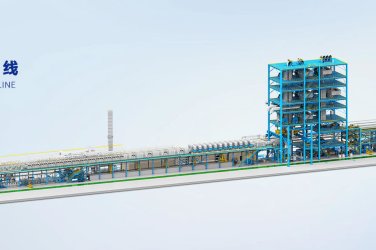

For enterprises, the efficient commissioning of a hot-dip galvanizing line is inseparable from systematic early-stage planning. The pre-sales customized service of RITMAN focuses on "Full-dimensional Production Line Preview." From process planning and logistics optimization to concealed works planning, it provides comprehensive support for the smooth implementation of production lines, serving as the core guarantee for high-efficiency commissioning.

In the process planning stage, RITMAN’s technical team works closely with the customer's actual product technology, capacity requirements, and specific workshop layout to conduct virtual simulations of every link in the hot-dip galvanizing line during the blueprint phase. Through iterative optimization, they ensure a rational process flow and seamless connection between segments, fundamentally avoiding low production efficiency caused by improper design.

Logistics turnover efficiency directly impacts the overall operating costs of the production line. RITMAN engineers utilize professional tools to simulate the actual movement paths of materials during production, accurately identifying potential inefficiencies such as detours or congestion. By scientifically optimizing the layout, they eliminate time and resource waste caused by logistics bottlenecks at the source, thereby reducing operating costs for the enterprise.

RITMAN’s pre-sales customized service covers all dimensions of early-stage planning for hot-dip galvanizing lines. With professional planning and extensive experience, they ensure that high-efficiency commissioning is no longer a challenge for enterprises.